Cartiere del Polesine’s production utilizes only secondary fibers, more precisely waste paper from waste sorting, from corrugated packaging and from converters’ shavings.

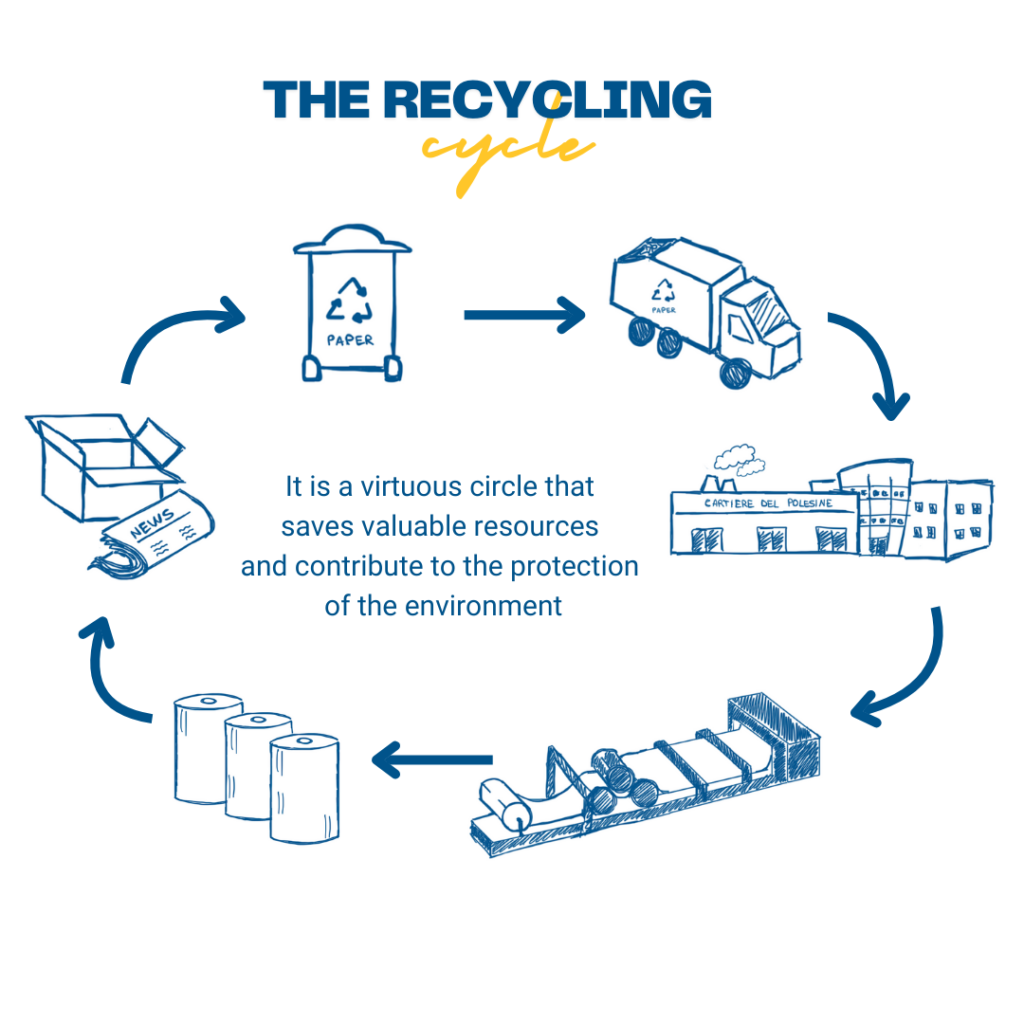

Our paper is used for corrugated board which, once used up, is recycled, and can be once again used as raw material. So the final product, corrugated packaging, is the most natural, recyclable and renewable package that exists and thus our paper returns to life becoming packaging once again, in a virtuous circle.

The Consorzio Nazionale Recupero e Riciclo degli Imballaggi a Base Cellulosica (Comieco) (National Body for Recovery and Recycling of Cellulose-Based Packaging) of which we are part, is the national guarantor of waste sorting and for setting up the recycling of paper and board.

The Body is active in the promotion of correct management and sorting of waste, urging the public to develop a “recycling culture” which can still find room for improvement in our country.